A good retrofit design is more than just new parts hung on a machine. Below we’ve pictured some of the things that make an AHS Retrofit a quality product.

Non-Industrial Equipment

You will NOT find non-industrial equipment in an AHS designed retrofit package. We believe that safety and reliability are too important to risk for the sake of a few dollars in savings.

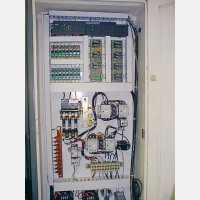

True System Integration

Although some retrofitters simply tie the new control to existing circuitry; AHS redesigns the machine's interface to gain the maximum benefits possible from the new Control. This usually involves removing or replacing substantial obsolete circuitry

Standard Industrial Parts

Whenever possible, we use standard "off-the-shelf" industrial components. In addition, we avoid using too wide a variety of components in a package. The idea is to reduce the need for large spare parts inventories, insure that replacements will be available, and to simplify troubleshooting.

Removal of unneeded circuitry

A major part of making a retrofit "fit", is the removal of all unused components and wiring. This doesn't just make the project look better, but it frees up space for the new hardware, and makes future troubleshooting much easier.

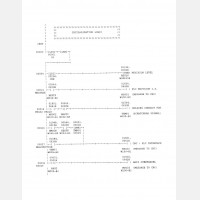

Documentation

All of our retrofit's come with sufficient documentation to provide complete troubleshooting capability by ANY trained technician. This includes schematics, wiring charts, and PLC ladder drawings. After all, why put new equipment on a machine, if you're not going to be able to maintain it?