Below are examples of our Milling Machine Retrofit Packages.

Brown & Sharpe VMC

This was one of the many Brown & Sharpe VMC's we've retrofitted. It had a removable rotary 4th axis and automatic tool changer.

Horizontal Milling machine

Six Axis control

This is an example of one our operator cabinets. This Dynapath retrofit was for a 6-axis European horizontal boring mill. The 5th and 6th axes were rotary, and the 6th was also removable.

We have done similar retrofits on Gilbert, Gidding & Lewis, Bullard, Wotan, and Cincinnati Mills. For most of our retrofits, we create custom engraved operator switch panels; although for some smaller standard mill retrofits we use a more generic silk-screened panel.

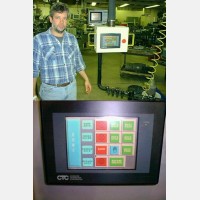

Manual Milling control

Although conversion to CNC would have been cost prohibitive on this horizontal boring mill, we were able to simplify the Operator Station. This small intuitive touch screen replaced a large confusing switch panel.

We have also retrofitted some large Giddings & Lewis Horizontal Dial Type Boring Mills by adding PLC's and touch-screens to replace the obsolete circuitry.

Knee Mill Packages

If your small CNC mill has an obsolete control, we have a perfect "bolt-on" package to replace it. The package includes replacement drives and motors.